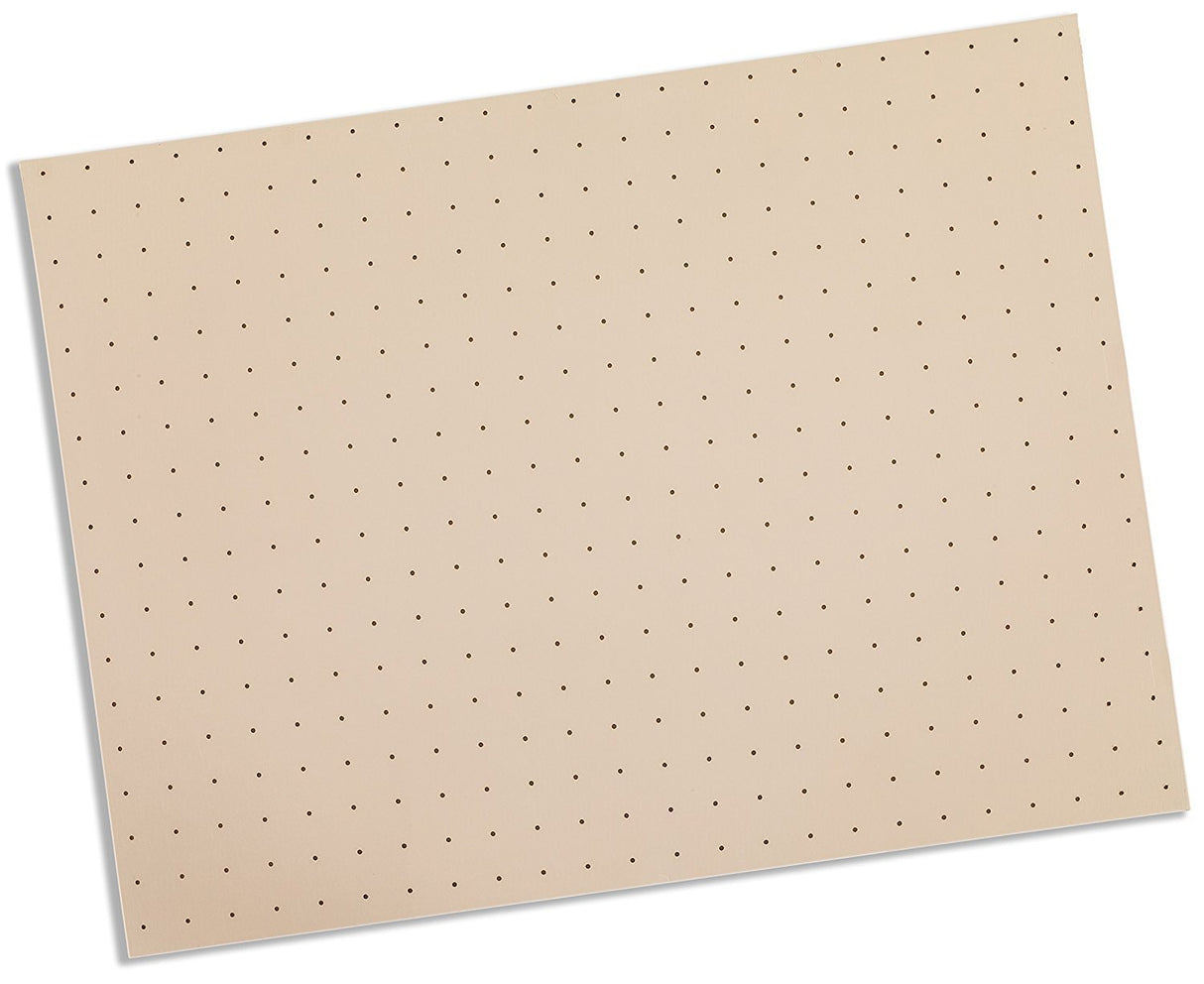

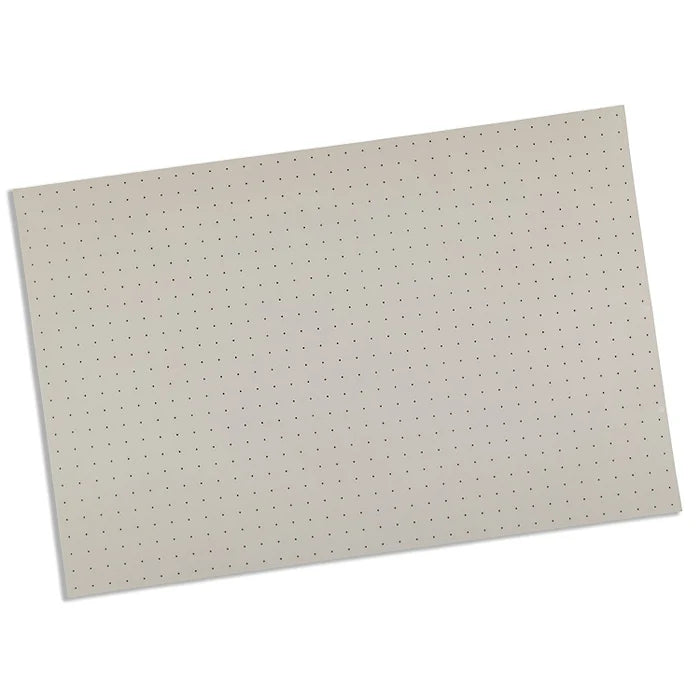

Rolyan Ezeform Thermoplastic Splinting Material

Rolyan Ezeform Thermoplastic Splinting Material - 1% Perforation / Blue / 18" X 24" X 1/8" (Cs/4) is backordered and will ship as soon as it is back in stock.

Shipping Information

Shipping Information

Product Information

Documents / Videos

Reviews

Rolyan Ezeform Gives Clinicians Control

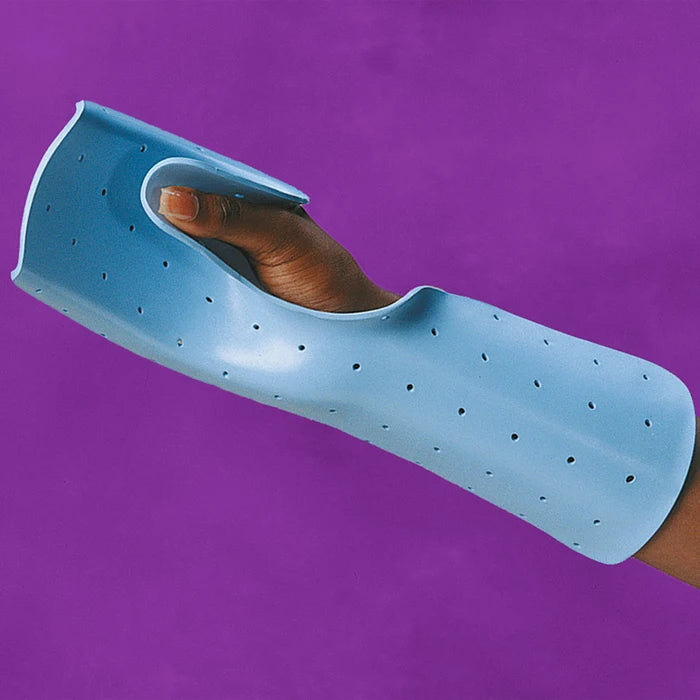

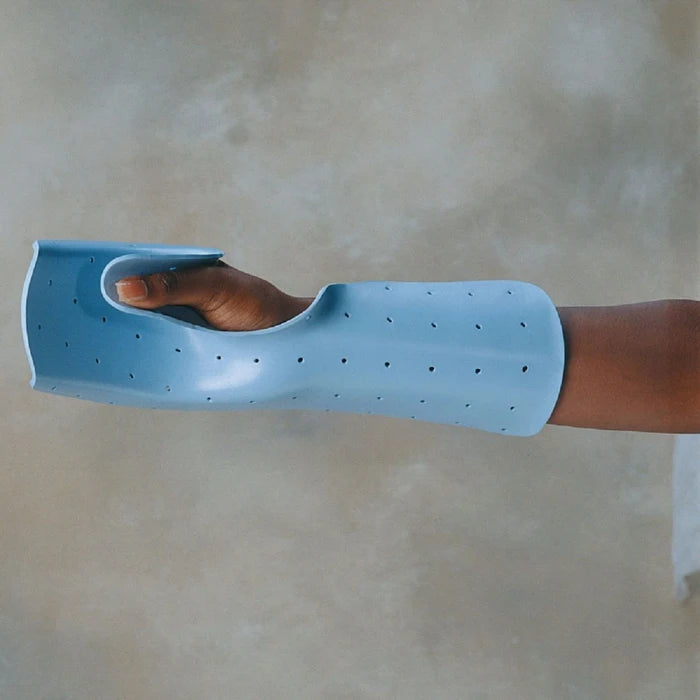

Ezeform is the only Rolyan splinting material with high resistance to stretch and moderate conformability. This gives the clinician maximum control when stretching out the material while also requiring less force during formation. Clinicians can produce medium or large intricate sheets that are perfect for hand splints, wrist splints, elbow splints, dynamic splints, pediatric splints, and more.

Custom Splint Molding

The clinician is in complete control with Rolyan Ezeform Thermoplastic Splint Material. With a maximum resistance to stretch, the material will not lose shape unless it is pushed or pulled in the desired direction and held until cool. That means unexpected patient movement will not cause the thermoplastic splint material to deform, and it will not stretch or deform when removed from a splint bath. When force is applied, the splinting material conforms to the surface contours and details. While it can be reheated and reshaped, the splint material will not return to its original shape.

Ezeform Splinting Material Properties

The Ezeform family of thermoplastic splint material is perfect for a variety of supportive needs. It is available in 1/8"" (3.2 mm), 1/16"" (1.6 mm) and 3/32"" (2.4 mm) sheet thicknesses with 1%, 19%, or solid perforation options. When the splint is hardened, it has a moderate/maximum rigidity of 40.7 kpsi* meaning it retains its shape without reinforcement.

Indications

Splinting materials are intended to be used for fabrication of custom-molded rigid splints, orthoses, and adaptive equipment.

Best uses include:

- Knee splints

- Shoulder splints

- Hand splints

- Wrist splints

- Elbow splints

- Dynamic splints

- Pediatric splints

- Foot drop splints

- Splints for spasticity

- Carpal tunnel splints

- Back supports

- Burn splints

- Static progressive and serial static splints

Care & Cleaning

Store at temperatures between 40° and 90°F (4° and 32°C) and less than 65 percent relative humidity. Avoid prolonged exposure to light, especially ultraviolet. Avoid exposure to corrosive and ethylene oxide fumes.

Formed splints will lose their shape in temperatures over 135°F(57°C) and should be kept away from sources of heat such as ovens, hot water, and car windows.

Clean splint with soap and lukewarm water. Allow splint and straps to dry thoroughly before reapplication.