Rolyan Polyflex II Thermoplastic Splinting Material

Rolyan Polyflex II Thermoplastic Splinting Material - Solid / White / 24" x 36" x 1/8" (Single Sheet) is backordered and will ship as soon as it is back in stock.

Shipping Information

Shipping Information

Product Information

Reviews

Rolyan Polyflex II Thermoplastic Splinting Material

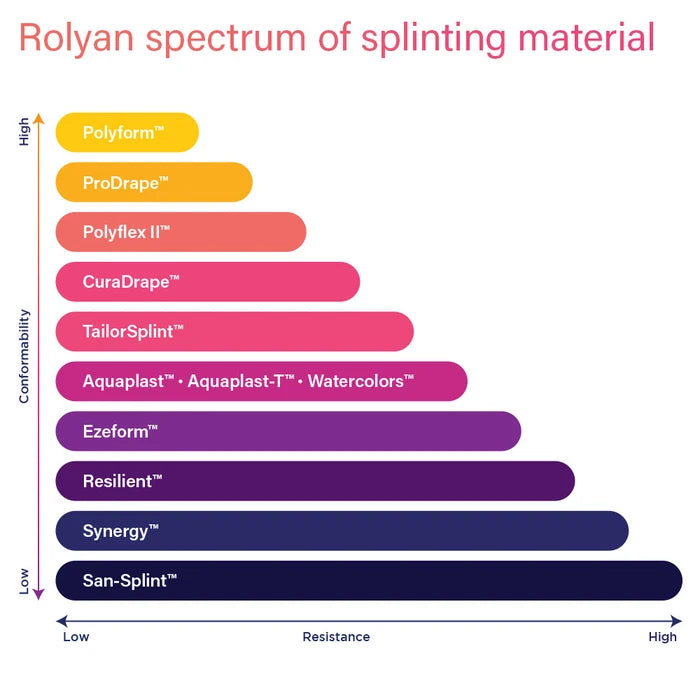

Polyflex II™, offers a balanced combination of high conformability and low resistance to stretch. With an outstanding natural drape — just less than Polyform — and ease of molding, it is an excellent choice for splints that require a precise fit. Polyflex II has a water-based, non-stick coating, which prevents accidental bonding. It can be reheated and reshaped repeatedly, but once it has been stretched, it will not return to its original shape.

Handling

Resistance to stretch: Minimum

- Stretches easily when heated.

- Use soft, gentle pressure to form a splint.

- Be careful not to allow material to stretch too much.

Conformability: Maximum

- Easily conforms to surface contours and detail, reducing time to fabricate splint, and provides a precise fit for increased comfort and fewer pressure areas.

- High degree of drape.

Memory: Minimum

- Ability to be reheated and reshaped but will not return to original shape.

Bonding: Coated

- Create a temporary bond by pinching together heated material; however, it will come apart when cooled.

- Form a permanent bond by scrubbing off the coating or removing it with a bond solvent.

Hardened Splint

Rigidity: Moderate/Maximum (49.8 kpsi*)

- Retains shape without reinforcement.

Surface: Smooth

- Picks up fingerprints and markings if not properly handled.

Indications

Splinting materials are intended to be used for fabrication of custom-molded rigid splints, orthoses, and adaptive equipment.

Best uses include:

- Thumb splints

- Finger splints

- Hand splints

- Wrist splints

- Elbow splints

- Dynamic splints

- Neck Collars

- Foot drop splints

- Carpal tunnel splints

- Pediatric splints

- Adaptive equipment

- Fracture braces

- Splints for arthritis

- Knee splints

- Flexor tendon repair splints

Care & Cleaning

Store at temperatures between 40° and 90°F (4° and 32°C) and less than 65 percent relative humidity. Avoid prolonged exposure to light, especially ultraviolet. Avoid exposure to corrosive and ethylene oxide fumes.

Formed splints will lose their shape in temperatures over 135°F(57°C) and should be kept away from sources of heat such as ovens, hot water, and car windows.

Clean splint with soap and lukewarm water. Allow splint and straps to dry thoroughly before reapplication.